GROUP NEWS

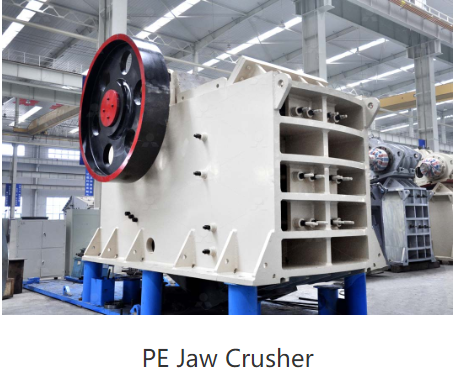

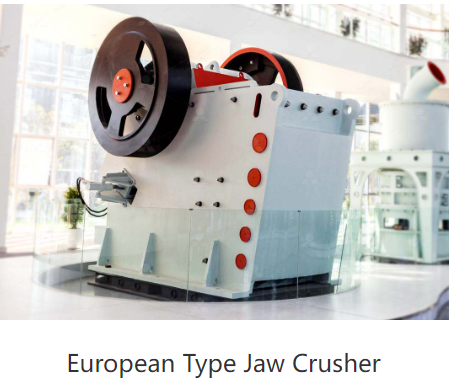

Comparing Jaw Crushers: Which Model Is Right for You

Are you in the market for a jaw crusher but unsure which model suits your needs best? This comprehensive guide breaks down the key factors to consider when comparing different jaw crusher models, helping you make an informed decision.

Performance Metrics: Compare factors such as maximum feed size, capacity, and reduction ratio across various models to assess their performance capabilities.

Operating Costs: Evaluate the energy consumption, maintenance requirements, and wear parts costs associated with each jaw crusher model to determine the most cost-effective option over its lifespan.

Technology and Features: Investigate the innovative features and technologies integrated into each model, such as hydraulic adjustment systems, anti-friction bearings, and automated settings, to understand their impact on performance and productivity.

Application Suitability: Consider the specific materials and applications for which each jaw crusher model is designed. Some crushers may excel in the primary crushing of hard rock, while others are optimized for the secondary or tertiary crushing of softer materials.

Size and Mobility: Determine whether a stationary or mobile jaw crusher better suits your operational requirements. Mobile crushers offer flexibility and maneuverability, while stationary crushers may provide higher production capacities and stability.

Environmental Considerations: Assess the environmental implications of each jaw crusher model, including noise levels, dust generation, and emissions, to ensure compliance with regulatory standards and minimize environmental impact.

User-Friendly Design: Look for user-friendly features such as easy access to maintenance points, intuitive control systems, and safety enhancements to enhance operator convenience and safety.

Customer Support and Service: Research the reputation of the manufacturer or supplier, including their after-sales support, spare parts availability, and service network, to ensure ongoing reliability and support throughout the lifespan of your jaw crusher.

By carefully comparing these factors across different jaw crusher models, you can confidently select the model that best aligns with your operational requirements, budget constraints, and long-term goals. Remember to prioritize reliability, performance, and efficiency to maximize the return on your investment in a jaw crusher.

CONTACT US

Related News...

Jaw Crusher vs Cone Crusher: How to Choose the Right Crusher for Your Mining Project

26/12/2025

Limestone Crushing Solutions for High-Capacity Aggregate Production

15/12/2025

Why Crushing Process Design Is Critical for Efficient Aggregate Production

11/12/2025

Copper Ore Crushing & Beneficiation: Complete Process, Equipment Selection and Performance Optimization

4/12/2025

Gold Ore Processing Equipment Selection Guide: How to Optimize Crushing, Flotation & Leaching for Efficiency

27/11/2025

Key Factors That Determine Jaw Crusher Cost

22/11/2025

Bluestone Crusher: Answers to the Most Common User Questions

13/11/2025

Pioneering Efficient Tracked Mobile Crushing and Screening Solutions

6/11/2025