On the land of Zimbabwe, a processing line specifically designed for quartzite gold ore is operating steadily. This production line, with its professional equipment configuration and efficient production process, provides a solid guarantee for local gold ore heap leaching operations.

Tailored for Quartzite Gold Ore Characteristics

This production line is custom-built according to the characteristics of quartzite gold ore. The feeding particle size can reach 500mm, and after a series of processing, it can produce finished materials of 0-15mm, which fully meets the material requirements for heap leaching. Moreover, the hourly output is stably maintained at 150 tons, and the efficient output gives more confidence to the advancement of the project.

On the land of Zimbabwe, a processing line specifically designed for quartzite gold ore is operating steadily. This production line, with its professional equipment configuration and efficient production process, provides a solid guarantee for local gold ore heap leaching operations.

Tailored for Quartzite Gold Ore Characteristics

This production line is custom-built according to the characteristics of quartzite gold ore. The feeding particle size can reach 500mm, and after a series of processing, it can produce finished materials of 0-15mm, which fully meets the material requirements for heap leaching. Moreover, the hourly output is stably maintained at 150 tons, and the efficient output gives more confidence to the advancement of the project.

Hardcore Equipment Configuration

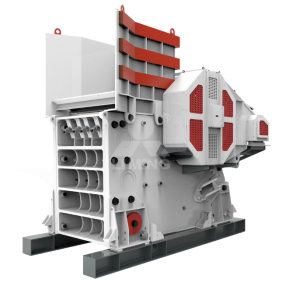

When it comes to equipment configuration, it is indeed the "hardcore" part of this production line. The GF0942 feeder is responsible for orderly feeding the quartzite gold ore raw materials into the next link, starting the processing journey. Then, the PE600x900 jaw crusher comes into play, undertaking the task of initial crushing to break large ore into appropriate particle sizes. The crushed materials then enter the HPT300 multi-cylinder hydraulic cone crusher for further crushing, making the ore particle size more refined.

The materials processed by the cone crusher will be transported to the S5X2160-3 vibrating screen for screening to ensure that the material particle size meets the standards of subsequent processing. After that, the SP1220 feeder takes over to accurately transport the materials to the next process. The complete set of steel structures and steel structure buffer silos make the layout of the entire production line more reasonable and the material transportation smoother. In addition, with the convenient key console, operators can easily control the operation status of the production line, making the operation convenient and efficient.

This Zimbabwe quartzite gold ore processing line, with its excellent performance and reliable operation, is becoming a powerful driving force for local gold mining industry development, bringing more possibilities for efficient gold extraction.