Basalt is widely used in high-performance concrete, asphalt pavement, railway ballast, and infrastructure projects due to its excellent mechanical strength and durability. However, basalt is also known as one of the most difficult materials to crush because of its high hardness and strong abrasiveness.

To achieve stable production, high-quality aggregates, and acceptable operating costs, basalt crushing requires a carefully engineered crushing and screening solution.

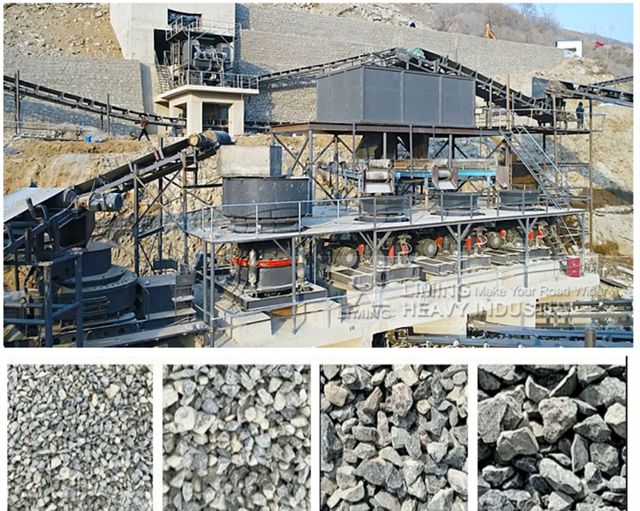

With extensive experience in hard rock applications, LIMING Heavy Industry provides reliable basalt crushing solutions tailored for high-strength aggregate production.

1. Crushing Challenges of Basalt

Basalt presents several technical challenges in crushing operations:

Very high compressive strength

Strong abrasiveness leading to rapid wear

Difficult-to-shape particles

High demand for equipment durability

These characteristics make basalt unsuitable for impact-dominated crushing systems in early stages. Improper equipment selection often results in excessive wear and frequent downtime.

2. Recommended Basalt Crushing Process Design

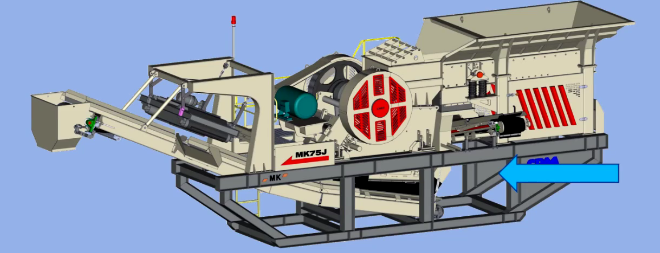

Primary Crushing: Heavy-Duty Jaw Crusher

Jaw crushers are ideal for basalt primary crushing due to:

Strong crushing force

Ability to handle large feed sizes

Excellent structural strength

Reliable operation under heavy loads

They efficiently reduce large basalt blocks into sizes suitable for secondary crushing.

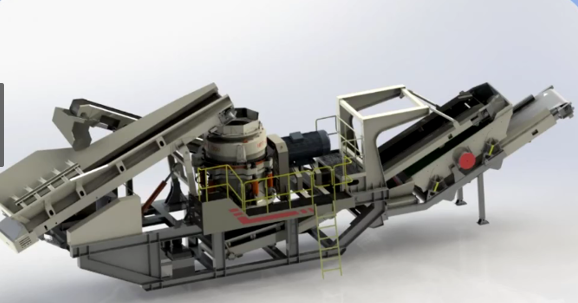

Secondary Crushing: Cone Crusher

For basalt applications, cone crushers are the most recommended secondary crushers.

Key advantages:

High crushing efficiency

Excellent resistance to abrasive wear

Stable continuous operation

Consistent product gradation

Cone crushers outperform impact crushers in basalt applications in terms of liner life and operating cost control.

Tertiary Crushing and Shaping (Optional)

When strict aggregate shape requirements are required, shaping stages can be added using:

Fine cone crushers

Vertical shaft impact crushers (VSI)

VSI crushers are typically used only in the final shaping stage to balance aggregate quality and wear cost.

3. Closed-Circuit Crushing and Screening System

Basalt crushing plants almost always adopt closed-circuit configurations.

Key benefits:

Precise control of final aggregate size

Elimination of oversized particles

Reduced re-crushing and energy waste

Stable product quality

High-efficiency vibrating screens play a critical role in maintaining consistent production.

4. Basalt Crushing Solutions by Capacity

Medium-Capacity Basalt Plants (200–400 TPH)

Typical configuration:

Jaw crusher

Cone crusher

Vibrating screen

Suitable for:

Regional road construction projects

Commercial aggregate supply

Large-Scale Basalt Crushing Plants (500–1000+ TPH)

Typical configuration:

Jaw crusher

Multiple cone crushers

Multi-deck vibrating screens

Suitable for:

Highway and railway projects

Large infrastructure developments

Continuous, high-output production

These systems are designed for maximum durability and long service life.

5. Wear Cost Control Strategies in Basalt Crushing

Because wear parts cost is a major concern, effective strategies include:

Selecting wear-resistant liner materials

Optimizing crushing chamber profiles

Maintaining consistent feed distribution

Avoiding unnecessary impact crushing

Engineering-based system design significantly reduces wear cost per ton.

6. Aggregate Quality in Basalt Crushing

High-quality basalt aggregates require:

Proper particle shape

Stable gradation

Controlled fines content

Combining compression crushing with final-stage shaping allows producers to meet strict infrastructure aggregate standards.

7. LIMING Heavy Industry Basalt Crushing Expertise

LIMING Heavy Industry provides complete basalt crushing solutions including:

Customized process design

Heavy-duty jaw and cone crushers

High-efficiency screening equipment

Professional engineering support

Each solution is tailored to project-specific requirements, ensuring reliable and cost-effective operation.

Conclusion

Basalt crushing demands robust equipment, optimized process design, and professional engineering support. With the right crushing solution, producers can achieve high-strength aggregates, stable production, and controlled operating costs.

By partnering with LIMING Heavy Industry, customers gain access to proven basalt crushing solutions designed for long-term performance.